Based on the RISE high-voltage grid-connected solution for wind power generation, voltage flicker and fluctuation are reduced by reasonably selecting the installation location and layout of the generating units and optimizing the design and parameters of the transmission lines.

Based on sensors and equipment data analysis, it monitors the data of the power generation system, equipment health status, etc., realizes fault early warning, diagnosis and localization, provides the basis for operation and maintenance management, and improves the reliability and operation efficiency of the system.

Based on the predicted power of power generation, the load demand of the power grid and the output of other power sources, it formulates a reasonable scheduling plan, realizes the coordinated operation of wind power generation and other power sources, and improves the acceptance capacity of the power grid for wind power.

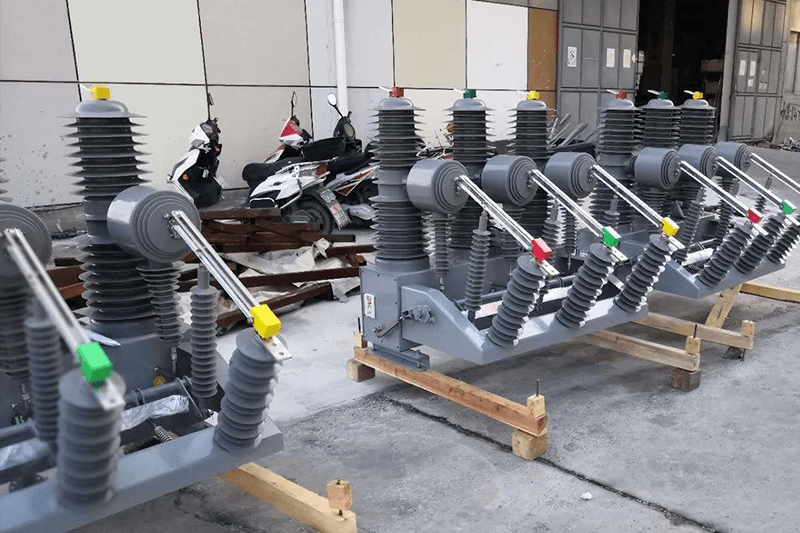

A new generation of integrated mechanism-switch assembly is adopted. The primary circuit conductive and transmission components are all sealed in the solid insulation embedded pole, which helps to avoid condensation and to realize highly reliable electrical and mechanical performance. The switch is maintenance-free.

Rolink pole-mounted switches can operate in Safety Zone 4 or Zone 2 to achieve more accurate O&M management. The switches are seamlessly connected to the RISE cloud platform to realize intelligent operation configuration, remote supervision and O&M of the pole-mounted switches.

The solution adopts optimized structural design, with small size, light weight, easy installation and construction. Streamlined operational lever design greatly reduces the risk of mis-operation and improves operability. Integration of digital control units is in line with the standardization requirements of the State Grid and Southern Grid.

Based on meteorological and historical data, machine learning and other methods, it establishes a power prediction model, builds an intelligent PV grid-connected scheduling platform, realizes the optimal matching of PV power generation and grid demand, and improves the acceptance capacity of the grid for PV power generation.

It monitors the voltage parameters at grid-connected points, establishes a voltage stabilization early warning system, and ensures that the grid voltage is within the normal range by regulating reactive power and adopting energy storage systems and other measures.

With RISE's information acquisition and management capabilities, it realizes remote monitoring and control of the PV power generation system, optimizes power generation efficiency, conducts fault diagnosis and maintenance management, and improves the system's intelligence level and operational reliability.

The solution adopts AI technology to monitor the behavior of staff, students and outsiders on campus in real time, accurately identify abnormal actions, and intrusion into dangerous areas, and send alerts. The recognition rules are continuously updated according to specific needs to ensure campus safety.

RISE+-based source-grid-load-storage-charge solution increases the proportion of green power on campus. It refines the monitoring of energy consumption data in teaching areas, etc. to establish energy consumption data. Energy consumption anomalies are found through timeline and horizontal comparison analysis to provide a basis for energy saving and consumption reduction.

With campus solution, the data connection of multiple sub-systems of the campus is achieved, such as security, energy, student management, etc. Multi-dimensional information is interrelated to form a collection of key information and provide powerful support for campus managers to achieve comprehensive information management.

Real-time monitoring of the charging station is made at load current, cable temperature and local discharge status. An alarm will be sent in case of overload, over-high node temperature and the abnormal local discharge. Thus, the safe operation of the charging station and the safety of personnel life and property can be guaranteed.

The solution makes real-time remote collection and analysis of the operating data and status of charging station equipment and facilities in order to reduce the investment of on-site inspection personnel. Through failure prediction and health management, it improves the accuracy of preventive maintenance, avoids the occurrence of equipment failure and lowers operating costs.

RISE platform accurately collects and analyses charging station operation data, accurately identifying low utilization charging equipment and energy consumption of the equipment itself, and providing data support for the optimization of operation and maintenance.

The intelligent ring main unit solution adopts a new generation of integrated mechanism & switch assembly with international patent. The interlock is simple and reliable. The cable compartment door is of maze structure with arc resistance, which can avoid personal injury. The electrical components are front-loaded for easy maintenance.

main units conform to standards and requirements of State Grid of China and China Southern Power Grid, two national grid corporations in China. Rolinks rain main units adopt distributed DTU of primary and secondary integration. Intelligent control units, key parameter sensors and miniaturized intelligent gateway constitute intelligent RMU. We realize remote monitoring, operation and maintenance through RISE platform.

RISE+ intelligent RMU solution covers RMU itself, its network, and all-round monitoring on its environment. This solution creates intelligent power use networks for railway stations, industrial parks and commercial centers to enjoy the experience of safety, efficiency, low-carbon and intelligence.

7X24 hours real-time monitoring is carried out on load and energy consumption in the industry park, including security, energy saving, low carbon, and electric energy quality. We provide key equipment failure prediction and risk alarms, prompting operation and maintenance personnel to intervene in advance to ensure the safety of power in the park.

We provide a complete source-grid-load-storage-charging construction, operation and management solutions. We offer full life-cycle services for energy upgrading and building green factories in parks.

The solution helps to reduce operation and maintenance costs. Through big data and intelligent algorithms, it accurately identifies high-consuming power equipment and power units, and provides decision-making support for energy-saving transformation.

We carry out holographic monitoring of switchgear, compensation cabinets, transformers and other key equipment operating parameters and environmental parameters in the substations. We also have a real-time mastery of the safe operation of the equipment.

We carry out all-round monitoring of key equipment such as switch temperature, local discharge, load, transformer noise, etc., and accurate prediction of equipment failure through machine learning. We manage scheduled inspections, preventive testing and elimination processes to reduce operation and maintenance costs.

We aim at the daily standard of carbon peak and carbon neutrality, implement accurate collection and deep analysis of line loss and power efficiency, and offers energy-saving reports to provide decision-making support for users to save energy and reduce carbon.

We focus on the national layout of the new computing power network system for the integration of data center, cloud computing and big data. Based on RISE platform, we perfect dynamic ring monitoring, and optimize air conditioning control strategy. In addition, we make an in-depth transformation solution, letting heat and coldness exchange deep into the cabinet heat source and greatly improving the heat exchange efficiency, energy saving and consumption reduction.

We realize 7X24-hour real-time monitoring. Failure prediction and risk alarms are implemented for key equipment to achieve the goal of failure pre-treatment and ensure the safety of power consumption in data centers.

As for light storage integration transformation construction and operation and maintenance management solutions for data centers, we enhance the green energy ratio of the data center and build a low-carbon and environmentally friendly data center.

The RISE platform's online monitoring, intelligent patrol, electrical fire, and other basic functions, in combination with the application of intelligent functions such as fault diagnosis and decision-making, equipment health assessment, and risk warning, ensure the safety of electricity in steel mill enterprises.

Through online monitoring, robots, video surveillance and AI recognition and other intelligent products, online visual O&M is realized, which helps to reduce the personnel investment required for traditional O&M and to improve the effectiveness of O&M.

The cost of electricity in steel mills accounts for around 10%. At the same time, the carbon emission intensity is at 2.5 tons. The RISE platform accurately follows up the carbon emission hotspots through the carbon tracking process to achieve accurate carbon sequestration, green energy introduction and other measures to reduce consumption and emissions.

Based on the analysis of buildings by RISE+ platform, we realize photovoltaic optimization as well as energy charging and discharging optimization to maximize efficiency and benefits of photovoltaic energy storage.

Based on the RISE+ platform and its environment, we integrate the building's access control, security, and fire systems to provide a collection of key information to enhance the efficiency and effectiveness of building management. We provide 3D building modelling rendering for key building facilities, making monitoring easier to see.

Based on RISE+, comprehensive management of water, electricity, gas and heat is carried out according to RISE+ region and level. Interactive closed-loop management of air-conditioning, lighting and personnel activities is implemented to minimize energy loss caused by operating habits. We horizontally compare the energy consumption coefficients of each area and level, offer energy consumption hotspots, and provide decision-making support for energy saving and consumption reduction.

Based on Rolinks' highly reliable switchgears and intelligent control units, sensors and miniaturized gateways, the operation of transformers and high- & low- voltage equipment are fully monitored in real time. In case of abnormality, real-time alarms will be activated to protect the reliable operation of the box transformer substation.

Rolinks smart box transformer substations can be seamlessly connected to the RISE platform for the decentralized characteristics of substation equipment. Users and O&M managers can get real-time information about the operation status of the box transformer substation. The platform's universal fault prediction and health management provide support for preventive intelligent operation and maintenance.

This creates an intelligent power network for end users such as railways, industrial production zones and commercial complexes, allowing users to gain the experience of safe, high-efficiency, low-carbon, and intelligent power use.

RISE+ platform monitors different AC and DC power supply grids, establishes a dynamic model of the load tide of the rail transport power supply system and implements fault prediction. It implements health management for key equipment, provides effective health warning, and improves power supply reliability.

The RISE + Rail Solution establishes the information network for the entire urban lines, creating an early warning mechanism for each station and reducing the need for maintenance personnel. At the same time, it enables horizontal comparison and analysis of big data from multiple lines to capture energy consumption hotspots and reduce operating costs.

With RISE's multi-data and multi-dimensional information collection and management capabilities, we apply electronic fence and AI identification technologies to holographically sense the operation of power supply stations and key equipment. We also realize load, environment and personnel interactive management, and ensure the overall operation safety of rail power supply network.

The solution makes real-time data collection and analysis of the production process, refines and optimizes management, reduces personnel input, lessens energy consumption, avoids material waste and equipment failure, improves resource and equipment utilization, thus lowering operating costs.

This solution remotely monitors the concentration of harmful gases in mines and the geological conditions of mines in real time, so that potential hazards and risks can be identified in a timely manner and preventive measures can be taken. At the same time, the direct contact of workers in hazardous areas is significantly reduced. This helps to lower the risk of accidents.

RIES's intelligent power supply system can provide real-time safety monitoring and health management of electricity used in mine production. It effectively prevents common failures of electricity consumption in mines, such as leapfrogging and leakage, and ensures the continuity of production and the safety of life and property.

Deeply integrated AI algorithm help to realize identification of grid forming and grid following operation modes, solving the problem of parallel operation with unstable external power supply networks. Based on accurate load prediction and grid parameter sensing capability, it can quickly realize the switching of operation modes and actualize the integration of autonomous intelligent energy networks.

High overload PCS devices with patented control algorithms and diverse prefabricated model intelligently provide voltage outputs required by the new power supply network through locally and remotely configured load information and power demand.

We constantly optimize the control algorithms and operation mod data analysis functions to improve the reliability and stability of the grid forming energy storage network and provide practical data support for the construction of a larger-scale new energy network.